Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

How Automated Welding Robots Are Transforming Modern Manufacturing

Traditional manual welding, though still widely used, often struggles to meet the rising demands of consistency, complex geometries, and labor shortages. This is where automated welding robots come into play, offering a transformative solution for manufacturers across industries.

As one of the leading China welding machine manufacturers, companies like Nanjing Haobo are at the forefront of developing smart, reliable, and scalable automated welding solutions tailored for modern production environments.

What Are Automated Welding Robots?

Automated welding robots are robotic systems programmed to perform welding tasks — typically arc, MIG, TIG, or spot welding — with minimal human intervention. These systems are often integrated into production lines and are capable of working 24/7, delivering precise and repeatable welds.

Depending on the production needs, these robots can be deployed in:

- Fixed stations

- On tracks (rail systems)

- Overhead or gantry configurations

- Collaborative settings with human operators

Key Advantages of Automated Welding Solutions

Whether you're a medium-sized fabricator or a global manufacturer, investing in automated welding solutions offers long-term benefits:

1. Enhanced Precision and Consistency

Manual welds can vary with operator fatigue or skill level. Robots maintain consistent parameters, resulting in uniform weld quality across thousands of units.

2. Increased Productivity

Robots don’t take breaks. They can work continuously, increasing throughput and reducing cycle times significantly compared to manual processes.

3. Improved Worker Safety

Welding environments involve intense heat, UV radiation, and toxic fumes. Robots reduce human exposure to these risks, improving overall workplace safety.

4. Reduced Waste and Rework

Accurate welding paths and stable processes reduce material waste and the need for post-welding corrections.

5. Adaptability for Complex Tasks

With the right programming and end-effectors, welding robots can handle complex geometries, multi-axis movements, and varying materials.

Types of Automated Welding Workstations by Application

At Nanjing Haobo, a specialized manufacturer of industrial automation systems in China, several types of welding workstations are engineered to suit different production layouts and application needs:

Inverted Rail-mounted Robot Welding Station

- Robot moves along a rail system mounted overhead, ideal for floor-space-limited environments.

- Great for automotive frames, structural parts, and container welding.

- Provides unobstructed access to large workpieces.

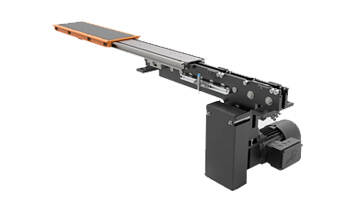

Floor-mounted Rail Robot Welding Station

- Traditional ground-mounted track system, allowing linear movement of the robot.

- Excellent for long workpieces like pipes, chassis, or beams.

- Enables synchronized welding operations across multiple stations.

Gantry Robot Welding Station

- Overhead gantry structure supports multidirectional robot movement.

- Ideal for large-scale workpieces and 3D welding paths.

- Commonly used in shipbuilding, heavy machinery, and wind power equipment fabrication.

Overhead Rail Robot Welding Station

- A variation of the inverted system, where the robot hangs from a ceiling rail and moves along the X-axis.

- Maximizes floor usage while maintaining high accessibility.

- Suitable for continuous production lines in automotive or large appliance industries.

These variations show how automation isn't one-size-fits-all — instead, it can be custom-engineered to fit space, product, and production flow constraints.

How to Choose the Right Automated Welding System

Selecting the right robotic welding solution depends on several factors:

- Part size and geometry

- Volume and production speed

- Weld type and joint complexity

- Factory floor layout

- Required flexibility for future upgrades

Partnering with experienced China welding machine manufacturers like Nanjing Haobo allows manufacturers to benefit from in-depth consultations, CAD-based layout planning, and tailored automation strategies.

Applications Across Industries

Automated welding robots are now essential in a wide array of sectors:

- Automotive frame and chassis production

- Agricultural machinery

- Steel structure and bridge fabrication

- Pressure vessel and pipeline welding

- Rail transit components

- Aerospace and energy sectors

With labor shortages and quality demands on the rise, industries are turning to automation not only to cut costs but to stay competitive in a globalized market.

Final Thoughts

As precision manufacturing becomes more important, automated welding solutions are now essential in the industry. With improvements in robot programming, sensor integration, and motion control, welding robots provide a dependable and scalable option for industrial automation.

For companies looking to advance their factory automation, partnering with reputable Chinese welding machine manufacturers like Nanjing Haobo offers access to expert knowledge, customized engineering solutions, and continuous technical support.

If you're interested in understanding how automated welding can improve your operations, stay tuned for more information or contact us to find the best solution for your needs.