Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Applications of Gantry Robots: Come See If Your Industry Needs One

Keeping production fast, accurate, and running smoothly is a challenge many factories face. If you’ve ever struggled with moving large parts, reaching across wide work areas, or trying to do the same task over and over with precision — you’re not alone. These are common issues in many industries.

That’s where gantry robots come in. They help automate big, repetitive, or hard-to-reach tasks with ease. But how do they actually work — and more importantly, would they make sense for your factory or project? Let’s take a look at how different industries are using gantry robots and see if your business could benefit too.

What Are Gantry Robots?

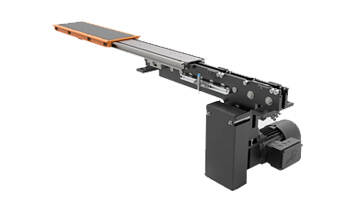

Gantry robots, also known as cartesian robots or portal robots, are robotic systems that move along multiple linear axes (typically X, Y, and Z) supported by a rigid frame. Their large work envelope, high repeatability, and structural stability make them ideal for heavy-duty and high-precision tasks.

Unlike robotic arms with limited reach and payload, gantry robots are designed for:

- Large workpieces

- Long linear travel distances

- Multi-process integration

- Complex motion control

At Nanjing Haobo, we specialize in designing and manufacturing gantry-based robotic systems — especially for automated welding, heavy component handling, and multi-station production lines.

Top Industries Using Gantry Robots

Let’s explore where gantry robots shine and why manufacturers across different sectors choose them.

1. Automotive Manufacturing

Use Cases:

- Robotic welding of car frames and body panels

- High-speed spot welding across large assembly lines

- Material handling and part positioning

Why Gantry Robots?

Automotive plants demand speed, repeatability, and the ability to move across wide work cells. Gantry robots, especially when mounted with welding heads or grippers, deliver precise control over vehicle body structures.

2. Heavy Equipment & Steel Fabrication

Use Cases:

- Welding structural beams, pipes, tanks

- Plasma or laser cutting of thick metal sheets

- Automated drilling or surface finishing

Why Gantry Robots?

Heavy industry requires robots that can handle massive loads, operate across long spans, and integrate seamlessly with rotary tables or positioners. Gantry systems with robust frames and multi-axis control offer an ideal solution.

3. Aerospace & Defense

Use Cases:

- Drilling and fastening of fuselage panels

- Precision welding of titanium or aluminum components

- Inspection and measurement automation

Why Gantry Robots?

Aerospace manufacturing calls for micron-level accuracy over large, sensitive components. Gantry robots provide smooth, controlled motion and can be integrated with vision systems and force sensors for quality assurance.

4. Shipbuilding & Renewable Energy

Use Cases:

- Robotic welding of wind turbine towers

- Assembly and joining of ship hulls or container structures

- Surface treatment (blasting, painting)

Why Gantry Robots?

Working on extra-large components demands scalable automation. Gantry robots — especially when designed with overhead or inverted configurations — give fabricators access to all sides of a component, without moving the part.

5. Electronics & Semiconductor

Use Cases:

- PCB assembly and soldering

- Wafer loading and inspection

- Micro-packaging and component placement

Why Gantry Robots?

In cleanroom environments, gantry systems offer precise, contamination-free movement. Their linear layout simplifies integration with conveyors, camera systems, and micro-handling tools.

Does Your Project Need a Gantry Robot?

If you’re still unsure whether a gantry robot is right for you, here’s a quick checklist:

- Are your parts large, heavy, or difficult to move?

- Does your production require multi-point welding, drilling, or assembly along a fixed path?

- Do you need precise and repeatable motion across long distances?

- Is floor space a constraint, making overhead or inverted installation appealing?

- Do you want to automate multi-station workflows without using multiple robots?

If you answered “yes” to any of these, your project may benefit from gantry robot integration.

Benefits Beyond Motion

Gantry robots are more than just motion systems. They can be:

- Equipped with welding heads, grippers, or cameras

- Synchronized with rotary stations and indexing tables

- Linked to MES systems for data-driven manufacturing

- Extended using 7th-axis systems for reach across workstations

With modular design, programmable motion control, and multi-axis coordination, they serve as the backbone for scalable automation systems.

Why Work with Nanjing Haobo?

As a specialist in robotic seventh-axis systems, gantry welding stations, and custom industrial automation, Nanjing Haobo helps manufacturers turn automation ideas into production-ready systems. We support multiple gantry configurations. Our team supports full-cycle delivery: from engineering consultation to manufacturing, integration, and support.

Final Thoughts

Whether you're building cars, ships, turbines, or circuit boards, gantry robots offer a powerful blend of precision, flexibility, and scalability. Their ability to automate complex tasks across large areas makes them a go-to solution for many modern manufacturing challenges.

Still wondering if your industry needs one?

Get in touch with our technical team — we’re happy to evaluate your project and recommend the best-fit gantry robot solution.