Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

What Is a Welding Robot and How Does It Work?

In modern manufacturing, the demand for faster production, higher precision, and safer working environments has driven the rise of welding robots. These machines are no longer limited to large automotive plants—they are now essential across industries from construction to shipbuilding. But what exactly is a welding robot, and how does it operate? This guide explains everything you need to know.

What Is a Welding Robot?

A welding robot is an automated machine designed to perform welding tasks with minimal human intervention. Using advanced sensors, controllers, and welding equipment, it can join metal components with remarkable accuracy and repeatability.

Unlike manual welding, where skill depends heavily on the welder’s training and experience, robotic welding ensures consistent quality across every weld.

Main Components of a Welding Robot

To understand how welding robots work, it’s important to look at their core components:

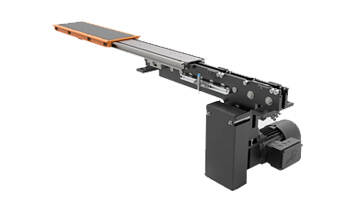

Robotic Arm – The mechanical arm that moves in multiple axes to position the welding torch.

Controller – The “brain” that processes programming commands and coordinates movements.

Power Supply – Provides the necessary electrical energy for the welding process.

Welding Torch – The tool that applies heat to join metals, customized for MIG, TIG, or spot welding.

Sensors – Detect position, joint gaps, and ensure precise alignment.

Wire Feeder (for MIG/TIG) – Feeds welding wire to the torch at a controlled rate.

Safety Enclosure – Protects workers from sparks, fumes, and intense light.

How Does a Welding Robot Work?

The operation of a welding robot follows a structured process:

Programming the Robot

The robot is programmed with movement paths, welding speed, and process parameters. Modern welding robots often use offline programming software, which allows engineers to set up tasks without stopping production.

Positioning and Clamping the Workpiece

Parts are placed in jigs or fixtures to hold them steady. This ensures that every weld happens in exactly the same position.

Torch Movement and Welding

The robotic arm moves the torch along the programmed path, applying the necessary heat and filler material. The robot adjusts for weld speed, arc length, and voltage in real time.

Quality Monitoring

Sensors and cameras monitor each weld for defects such as porosity or misalignment. Some systems use AI to make automatic corrections.

Cooling and Final Inspection

Once welding is complete, the joint is allowed to cool before inspection, either by a quality control technician or by automated vision systems.

Common Types of Welding Robots

Different industries require different welding methods. The most common robotic welding types include:

MIG (Metal Inert Gas) Welding Robots – Ideal for high-speed, high-volume production lines, such as automotive frames.

TIG (Tungsten Inert Gas) Welding Robots – Used for precision work on thin materials like stainless steel.

Spot Welding Robots – Common in automotive body assembly for joining sheet metal.

Arc Welding Robots – Versatile and widely used for general fabrication.

Advantages of Welding Robots

Implementing welding robots offers several business advantages:

Higher Productivity – Robots work continuously without fatigue.

Consistent Quality – Every weld meets the same standard.

Improved Safety – Reduces human exposure to fumes, heat, and sparks.

Cost Savings – Fewer reworks, lower scrap rates, and faster production cycles.

Scalability – Easily reprogrammed for different products.

Applications Across Industries

Welding robots are used in:

Automotive manufacturing – Chassis, exhaust systems, and body panels.

Construction and steel fabrication – Beams, frames, and structural components.

Shipbuilding – Large-scale welding in challenging environments.

Agricultural equipment – Heavy-duty machinery frames.

Conclusion

A welding robot is more than just a tool—it’s a strategic investment in productivity, quality, and safety. Whether you’re in automotive, construction, or heavy manufacturing, robotic welding can give your business a competitive edge.

At Nanjing Haobo, we specialize in advanced welding robot manufacturing, delivering solutions tailored to your production needs. Contact us today to explore how our welding robots can transform your operations.