Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Which Industries Need a Robot Seventh Axis?

What if your robots could do more—without needing more floor space?

As automation reshapes modern manufacturing, many operations hit the same roadblock: how to maximize robotic flexibility when space and efficiency are non-negotiable.

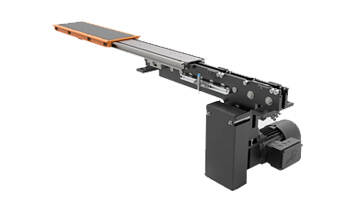

The 7th-axis robot track transforms stationary 6-axis arms into mobile powerhouses. By adding linear motion, it unlocks:

- Extended reach across multiple workstations

- Space-saving layouts for cramped facilities

- Faster cycle times without costly cell duplication

But which industries gain the biggest competitive edge from this equipment? And why are forward-thinking factories calling it their ‘secret weapon’? Let's break it down.

1. Automotive Industry

The automotive sector is one of the earliest adopters of robotic automation—and it remains one of the largest users of seventh axis systems.

Key Applications:

- Robotic welding on large car body frames

- Linear movement between multiple stations on a production line

- Seamless integration into modular, reconfigurable manufacturing cells

The seventh axis enables car manufacturers to extend robot reach without compromising speed or precision, which is crucial for handling vehicle chassis, doors, and panels.

2. Metal Fabrication and Welding

In welding-intensive industries, fixed robotic arms often fall short in covering large or oddly shaped workpieces. The seventh axis allows the robot to travel along the part, rather than repositioning the workpiece or installing multiple robots.

Benefits for Fabrication:

- Better coverage of long seams or heavy components

- Reduces equipment redundancy

- Improves weld consistency and production throughput

3. Warehousing and Logistics

As automated storage and retrieval systems (AS/RS) become standard in smart warehouses, robotic arms with extended travel capability are increasingly in demand.

Seventh Axis Applications:

- Picking and placing from multiple pallet racks

- Sorting goods over long conveyor systems

- Mobile gantry systems for high-bay storage environments

By adding a seventh axis, companies improve space efficiency and eliminate the need for multiple static robotic arms.

4. Electronics and Semiconductor Manufacturing

This industry deals with delicate and highly precise assembly processes that span multiple micro-stations.

Why the Seventh Axis Helps:

- Allows precision robots to move between high-density tool stations

- Supports flexible assembly lines for multiple product types

- Saves cleanroom space by avoiding redundant robots

5. Aerospace and Shipbuilding

These sectors involve extra-large components, such as airplane fuselages or ship hulls. Manual labor or gantry cranes are often used, but integrating robotic seventh axes offers automation with high precision.

Key Use Cases:

- Automated drilling or sealing of large structural parts

- Coating, cleaning, and inspection of wide surfaces

- Multi-point servicing with a single robot system

6. Furniture and Woodworking

Large furniture pieces often need surface treatment, gluing, or machining across broad surfaces.

Benefits Include:

- Handling long workpieces without manual repositioning

- Automating repetitive sanding or painting

- Moving seamlessly between different workstations

7. General Industrial Assembly

In many medium- to large-scale manufacturing lines, the need for flexibility and adaptability is growing. A seventh axis allows robotic systems to scale with production.

Typical Scenarios:

- Connecting multiple small work cells

- Extending existing robot work envelopes

- Providing redundancy-free automation for long parts

Conclusion:

From automotive welding to semiconductor assembly, the seventh axis is helping more industries increase robot utilization, reduce costs, and boost productivity. As automation evolves, sectors that previously relied on fixed or stationary systems are now rethinking their layouts to embrace dynamic, track-based robot movement.

If your industry handles large parts, long processes, or high-volume flows, adding a robotic seventh axis may be the next step toward leaner, smarter manufacturing.

If you need to customize or purchase a high-performance seventh-axis system, please feel free to contact Haobo - we are dedicated to providing a one-stop industrial automation solution.