Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Gantry Robots for Automotive Manufacturing: Driving Precision, Efficiency, and Smart Production

The Growing Demand for Precision and Efficiency

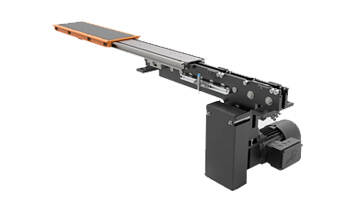

The automotive manufacturing industry has always demanded high precision, consistent quality, and scalable production capabilities. Modern production lines are increasingly challenged to meet these expectations while optimizing efficiency and minimizing human error. In this context, gantry robots for automotive manufacturing have emerged as indispensable tools, reshaping the landscape of vehicle assembly and component handling. Unlike traditional robotic arms, gantry robots operate across large workspaces with multi-axis linear motion, enabling them to perform complex assembly, welding, material handling, and part positioning tasks with remarkable accuracy and repeatability. Their structural rigidity and high load-bearing capabilities allow them to handle both lightweight components and heavy assemblies, providing flexibility for various stages of the automotive production process.

Combining Speed, Accuracy, and Safety

In contemporary automotive factories, speed and precision must go hand in hand. Gantry robots excel in this regard by integrating advanced servo motors with finely tuned control algorithms, allowing for smooth, fast, and reliable motion along the X, Y, and Z axes. This combination of mechanical strength and intelligent control ensures that parts are positioned and assembled accurately, significantly reducing production defects. Beyond accuracy, these robots contribute to operational safety by removing human operators from repetitive or hazardous tasks, such as lifting heavy assemblies, handling hot or sharp components, or performing high-speed welding operations.

Strategic Benefits for Automotive Manufacturers

The deployment of gantry robots in automotive manufacturing is not limited to production efficiency alone; it also drives strategic benefits. By integrating these robots into automated assembly lines, manufacturers gain the ability to scale production dynamically to meet market demands. Real-time data collected from gantry systems can be fed into Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) platforms, providing actionable insights into workflow optimization, predictive maintenance, and inventory management. Furthermore, the modularity and customizability of these robots allow manufacturers to adapt to changing vehicle designs, production volumes, and assembly sequences without extensive line reconfiguration, thus enhancing flexibility and return on investment.

Nanjing Haobo Intelligent: Leading the Automation Revolution

Among the companies leading this transformation, Nanjing Haobo Intelligent Equipment Co., Ltd. stands out as a premier provider of advanced gantry robot solutions for automotive manufacturing. The company occupies over 19,000 square meters and focuses on the research, development, and manufacturing of robotic seventh-axis systems and gantry robot series. Nanjing Haobo combines a skilled workforce of experienced engineers with years of collaborative experience with top-tier domestic and international enterprises. Its products have been widely adopted in sectors including steel heavy industry, rail transportation, new energy, aerospace, and most notably, automotive manufacturing. By delivering high-precision, high-speed, and customizable gantry robots, Nanjing Haobo enables automotive manufacturers to optimize assembly line performance, enhance product quality, and reduce operational costs.

With a commitment to innovation, quality, and intelligent automation, Nanjing Haobo Intelligent upholds the philosophy of "Integrity as the Foundation, Exceptional Quality" and adheres strictly to the ISO9001:2015 quality management system. Its solutions have been implemented in partnerships with industry leaders such as Volvo, GAC, NIO, and other prestigious companies, demonstrating the company's capability to meet the complex demands of modern automotive production. Through these advanced gantry systems, manufacturers can not only achieve higher efficiency and precision but also transition toward a fully integrated, smart factory environment that leverages automation, data analytics, and adaptive production strategies.

Contact Us: Explore how Nanjing Haobo Intelligent can enhance your automotive manufacturing operations with advanced gantry robots and tailored automation solutions.