Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Gantry Robots for Material Handling: A Deep Dive into Technology, Design, and Future Trends

Material handling has always been one of the most labor-intensive and safety-sensitive processes in industrial production. Moving heavy loads, positioning components with millimeter-level precision, and ensuring reliable long-term operation under demanding conditions require advanced automation. This is where Gantry robots for material handling have emerged as one of the most powerful solutions.

Unlike traditional robotic arms, gantry systems operate on Cartesian coordinates, utilizing linear motion along X, Y, and Z axes. This allows them to handle large workspaces, heavy payloads, and complex trajectories with high precision. In this article, we will provide a comprehensive exploration of gantry robots in material handling, including their design principles, mechanical structure, control systems, integration considerations, and future developments.

1. Mechanical Architecture of Gantry Robots

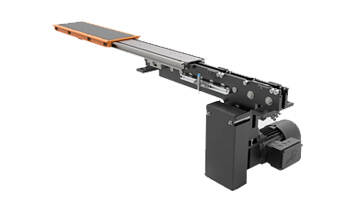

The defining characteristic of gantry robots lies in their structural rigidity and large working envelope. The mechanical framework usually consists of:

Steel profiles or aluminum alloy beams: Provide structural stiffness while minimizing vibration during motion.

Linear guides and gear racks: Enable smooth and precise translation, capable of handling both axial and radial forces.

Multi-axis configuration: Typically two-axis or three-axis, with three-axis most common in material handling applications.

Load-bearing modules: Customizable grippers, lifting tools, or vacuum systems attached to the moving carriage to interact with materials.

By positioning the robot overhead, gantry systems maximize workspace utilization and reduce interference with ground-level operations. For industries dealing with large or heavy objects, such as steel, automotive components, or aerospace parts, this structural advantage is significant.

2. Working Principle

Gantry robots for material handling operate using Cartesian coordinate logic. Each axis moves independently in an orthogonal direction:

X-axis: horizontal travel, usually across the length of the workspace.

Y-axis: horizontal travel perpendicular to X, defining the width of the workspace.

Z-axis: vertical travel, enabling lifting and lowering of materials.

Precision comes from:

High-quality servo motors with closed-loop feedback.

Advanced control algorithms that smooth acceleration and deceleration curves.

Structural reinforcement that minimizes deflection under heavy loads.

This configuration ensures motion accuracy within fractions of a millimeter, even across workspaces spanning several meters.

3. Control and Feedback Systems

A gantry robot’s reliability heavily depends on its control system. Advanced setups typically include:

Closed-loop servo control: Maintains position even after sudden stops or power interruptions.

Absolute encoders: Retain positional data for instant restart without recalibration.

Vibration suppression algorithms: Reduce oscillations when handling large or suspended loads.

Safety-rated control functions: Features like STO (Safe Torque Off), SS1 (Safe Stop 1), and SLS (Safe Limited Speed) compliant with ISO 13849 or IEC 62061 ensure safe human-machine interaction.

4. Integration Considerations

Modern factories require seamless integration of robots into production lines. Gantry robots achieve this via:

PLC and fieldbus interfaces: Support Profinet, EtherCAT, or Ethernet/IP for smooth communication.

MES/ERP compatibility: Real-time data collection enables production scheduling, inventory monitoring, and predictive maintenance.

Optional inline inspection: Onboard cameras or laser scanners can handle part alignment, quality checks, and measurement verification.

Integration transforms gantry robots into intelligent nodes within Industry 4.0 ecosystems.

5. Key Performance Parameters

Critical specifications for evaluating gantry robots include:

Maximum speed: Up to 4 m/s for advanced three-axis models.

Payload capacity: Fully customizable based on structural reinforcement.

Precision: Sub-millimeter repeatability across long travel distances.

Materials: High-strength steel for load-bearing parts, aluminum alloys for lightweight sections.

Control software: Should allow flexible programming for complex trajectories while remaining intuitive.

These parameters allow gantry robots to outperform conventional handling systems in both productivity and reliability.

6. Advantages of Gantry Robots for Material Handling

High payload capability: Handles loads beyond the range of most articulated arms.

Large workspace coverage: Can span entire production lines or assembly areas.

Scalability and customization: Easily adapted to specific layouts or material types.

Durability: Designed for continuous, heavy-duty operation.

Reduced downtime: Modular designs like detachable bearing wheels simplify maintenance.

7. Challenges and Considerations

While the benefits are clear, certain aspects must be addressed:

Initial cost and footprint: Requires significant space and capital investment.

Structural rigidity: Poor design may lead to deflection or vibration issues.

Integration complexity: Advanced controls demand careful synchronization with existing systems.

Proper planning and collaboration with suppliers, such as Nanjing Haobo Intelligent, are essential to mitigate these challenges.

8. Industry Trends and Future Outlook

Electrification and renewable energy: Handling large batteries, solar panels, and wind turbine components.

Rail and aerospace expansion: Increasing automation in assembly and maintenance of large-scale vehicles.

Smart factories: Gantry robots becoming integral nodes in IoT-enabled production lines.

Safety and collaboration: New designs emphasize safe human-robot interaction through enhanced safety functions.

These trends position gantry robots as not just tools for today but foundational elements of intelligent manufacturing.

9. Nanjing Haobo Intelligent: A Reliable Partner

Nanjing Haobo Intelligent offers high-performance three-axis gantry robots featuring:

Robust construction with steel profiles and roller linear guides.

High-speed operation up to 4 meters per second.

Customizable payload solutions tailored to client requirements.

ISO 9001:2015 certified manufacturing ensuring consistent quality.

Ease of maintenance with detachable bearing wheels.

These systems are designed for industries such as steel fabrication, automotive, rail transit, renewable energy, and aerospace, delivering reliable and efficient automation solutions.

Gantry robots for material handling have evolved into highly sophisticated automation platforms. Their structural strength, precision, and integration capabilities redefine efficiency, safety, and scalability in industrial environments.

For manufacturers seeking advanced automation, partnering with reliable suppliers like Nanjing Haobo Intelligent ensures performance, customization, and long-term support.

Contact Us: Reach out to Nanjing Haobo Intelligent today to explore how gantry robots can optimize your material handling workflow.