Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Why Top Factories in China Are Investing in 3-Axis Gantry Robots Now

Have you noticed how fast China’s factories are advancing lately? If you've been wondering what’s powering their next-level automation, you're not alone. One of the biggest game-changers flying under the radar is the 3-axis gantry robot—a technology that's quietly transforming production lines across industries like automotive, aerospace, electronics, and steel fabrication.

So why are so many top factories in China betting big on these machines right now?

In this post, we’re diving into what 3-axis gantry robots actually do, why they’re gaining so much attention, and how they’re helping manufacturers work faster, smarter, and more precisely than ever before. Whether you’re in the industry or just curious about the future of factory automation, you’re in the right place. Let’s break it down.

What Is a 3-Axis Gantry Robot?

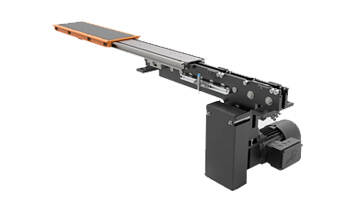

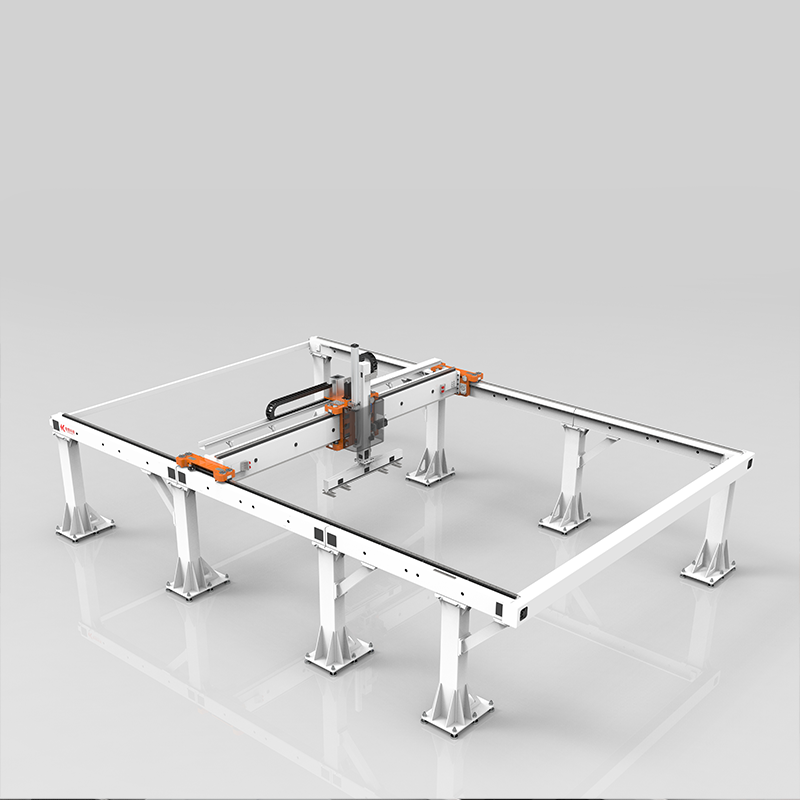

A 3-axis gantry robot is a type of Cartesian robot that moves along three linear axes: X (horizontal), Y (vertical), and Z (depth). Built on a rigid frame, these robots are ideal for tasks that require precision, repeatability, and large-area coverage. They can be integrated with end-effectors for welding, handling, packaging, or inspection—making them highly adaptable for many applications.

Why Are Chinese Factories Prioritizing 3-Axis Gantry Robots?

1. Massive Efficiency Gains

Factories are under constant pressure to increase output while reducing labor costs. 3-axis gantry robots automate repetitive tasks like material loading, welding, or positioning, achieving consistent speeds and accuracy. One robot can often replace multiple manual operators, leading to significant cost savings over time.

2. Excellent for Large and Heavy Workpieces

Many of China’s top factories, particularly in sectors like rail transit, automotive, and steel processing, deal with heavy, bulky parts. The 3-axis gantry system offers a large working envelope and strong payload capacities, making it ideal for handling large components that conventional robotic arms can’t reach or lift.

3. High Precision and Repeatability

Chinese manufacturers are producing increasingly complex and high-tech products. Precision has become non-negotiable. With advanced control systems, 3-axis gantry robots achieve sub-millimeter accuracy, ensuring quality in tasks like welding seams, laser cutting paths, or precise component placement.

4. Integration with Smart Factory Systems

As Industry 4.0 continues to reshape manufacturing, smart factories are becoming the norm. Gantry robots can be easily integrated with IoT systems, machine vision, PLCs, and MES software, creating a fully digitized production line that offers real-time monitoring and data-driven process optimization.

5. Versatile Across Multiple Industries

Whether it's stacking in a warehouse, welding structural parts, or assembling industrial machinery, 3-axis gantry robots can be customized for countless use cases. This versatility is a big reason why factories across China’s automotive, energy, heavy machinery, and electronics sectors are investing in them.

Key Features That Make 3-Axis Gantry Robots a Smart Investment

- Modular Design: Can be scaled or customized according to floor space and application.

- High Load Capacity: Perfect for handling steel beams, rail components, or large enclosures.

- Reduced Downtime: With preventive maintenance systems and durable linear tracks, uptime is maximized.

- Flexible Mounting Options: Can be mounted overhead, floor-based, or suspended—saving valuable factory space.

What This Means for the Global Market

Chinese factories aren’t just manufacturing for local demand—they are producing for global export markets. The adoption of advanced gantry systems enhances their ability to meet international quality standards, handle high-volume orders, and compete with manufacturers from Europe, Japan, and the U.S.

Factories that don’t upgrade risk falling behind. For international partners and sourcing companies, working with factories equipped with 3-axis gantry robots means more consistent quality, faster lead times, and better reliability.

How to Choose the Right 3-Axis Gantry Robot

Before investing in or partnering with a supplier using gantry automation, consider:

- Working Area Requirements: How large is the material or product?

- Load Capacity: Is it for light handling or heavy fabrication?

- Accuracy Needs: Are you performing high-precision assembly or general handling?

- Integration: Can it be linked with existing automation or IoT platforms?

Companies like Nanjing Haobo offer customized solutions tailored to specific industry needs—ensuring your investment meets production goals without overcomplicating your workflow.

Conclusion: Gantry Robots Are No Longer Optional—They're Essential

China's top factories are not just keeping up—they’re setting the pace in industrial automation. 3-axis gantry robots have emerged as a cornerstone of that progress, delivering unmatched efficiency, precision, and versatility. Whether you’re a manufacturer, OEM, or sourcing partner, understanding the power of these systems is crucial for making smarter decisions in today’s competitive industrial world.

If you're looking to upgrade your operations or partner with a supplier that leverages high-performance gantry automation, reach out to Nanjing Haobo for a tailored consultation.