Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Important parts

Important parts

(4)The important parts of a Telescopic Fork System are crucial for its operation, durability, and efficiency. Each component plays a specific role in ensuring the system can extend, retract, and carry heavy loads safely. Below are the key parts of a telescopic fork system:

1. Forks (Fork Arms)

- Function: The main lifting component, used to carry or support materials.

- Features: Typically made from steel or high-strength alloys to withstand heavy loads. They are designed to extend and retract to adjust the reach and load capacity.

2. Telescopic Arm

- Function: The core structure of the system that allows the forks to extend and retract.

- Features: This arm consists of multiple segments that slide into each other. The strength and smooth movement of the telescopic arm are essential for the system's functionality.

3. Hydraulic System

- Function: Powers the movement of the telescopic arm (extend and retract).

- Features: This system includes a hydraulic cylinder, hoses, valves, and a pump. The hydraulic system provides the force necessary to extend or retract the forks based on operator commands.

4. Hydraulic Cylinder

- Function: A critical component of the hydraulic system that controls the extension and retraction of the telescopic forks.

- Features: A robust cylinder filled with hydraulic fluid that, when pressurized, forces the forks to extend. When the pressure is released, it retracts the forks.

5. Frame or Chassis

- Function: The main body or structure that supports the telescopic fork system.

- Features: Made of heavy-duty material (usually steel), the frame houses the telescopic arms, hydraulic cylinders, and other components. It ensures that the entire system is stable and secure during operation.

6. Extension Mechanism (Sliding or Telescopic Mechanism)

- Function: The mechanism that allows the forks to slide in and out, providing the desired length and reach.

- Features: This mechanism typically includes rails, sliding bushings, and locking pins that help extend or retract the forks smoothly.

7. Fork Attachment

- Function: This part connects the forks to the base of the system (e.g., forklift or telehandler).

- Features: Often adjustable, it allows the forks to be positioned at different angles or heights to handle different load sizes and types.

8. Control System

- Function: Allows the operator to control the movement and extension of the forks.

- Features: This can be a manual control system or a more advanced electronic control system. It often includes buttons, levers, or joysticks to operate the hydraulic system and adjust fork positions.

9. Safety Locks or Pins

- Function: To secure the fork in place and prevent accidental extension or retraction during non-operation.

- Features: These locks or pins engage and disengage to ensure the forks remain stable and safe when not in use or when lifted at maximum height.

10. Lift Cylinder

- Function: Lifts the entire system or forks vertically.

- Features: Located in the frame, it works in tandem with the hydraulic system to raise the fork arms or load to the desired height.

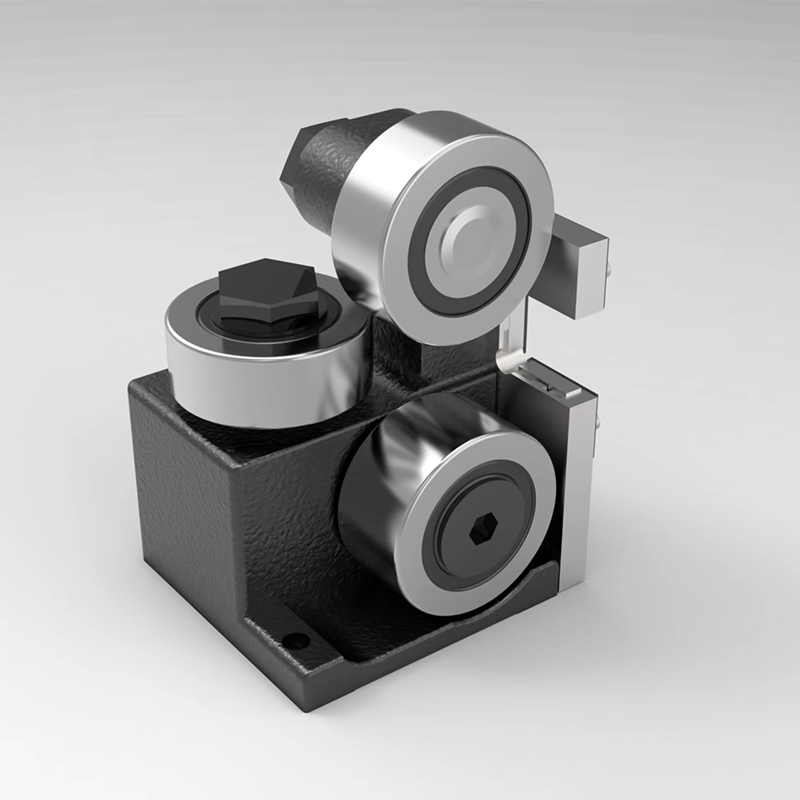

Linear guideways

Linear guideways, also known as guide rails, are critical linear motion components in industrial automation, providing smooth and precise guidance for moving parts along horizontal or vertical axes. These linear guideways are essential for maintaining accuracy and stability in various mechanical equipment, from machine tools to automated systems and sliding door mechanisms.

Positioner

The Positioner is a versatile component in industrial automation, designed to manipulate workpieces into various positions for processes such as welding, painting, and inspection. It enhances operational flexibility and efficiency through its multi-axis movement capabilities, integrating precision mechanisms like RV reducers and servo motors for high-accuracy positioning.

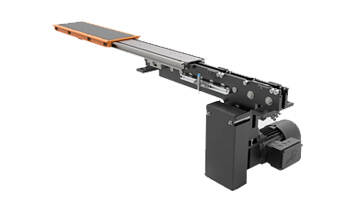

Rack

The rack, also known as a gear rack, is a linear motion control component pivotal in converting rotational motion into linear motion within industrial automation systems. Known for its precision, load-bearing capacity, and durability, our racks are engineered to deliver high-accuracy positioning essential for various automated machinery and equipment.

Pinion

Pinions are essential components in industrial automation, serving as the backbone for mechanical power transmission and motion conversion. Our pinions are precision-engineered toothed wheels designed to convert rotational motion, adjust speeds and torques, and provide accurate directional changes in various automated systems.